Planetary Gear Boxes

Planetary gear boxes, also known as planetary gearboxes, are one of the most interesting types of gearboxes in motion control.

Planetary Gearboxes For Sale

-

060Pabz180 Coaxial Precision Mini Planetary Gearbox for CNC Machine

-

52mm Metal Cutted High Precious Low Noise Planetary Gearbox

-

90mm Square Flange 10:1 Servo Motor High Torque Planetary Automation Gearbox

-

Automatic Power Transmission Gear Reducer Planetary Speed Reduction Gear Motors 4mm

-

High Efficient Coaxial Inline Servo Motor Precise Low Backlash Precision Gearbox, Planetary Gear Box

-

Prf Series Ratio 3-100 Transmission 1500W Servo Motor Planetary Gearbox

Leading the Industry in High-Performance Planetary Gearboxes

Our company Transmission Co., Ltd. is a leading manufacturer in the mechanical transmission industry for over two decades, specializing in the production and sale of high-quality planetary gearboxes. With state-of-the-art facilities, advanced technology and a team of dedicated engineers, we are proud to serve the global market, providing powerful and reliable gear solutions for a variety of applications.

Designed with precision and durability in mind, our planetary gearboxes feature compactness, high torque and strong load-carrying capacity. These gearboxes are widely used in automotive transmissions, industrial machinery, robotics, renewable energy systems and heavy equipment where performance and efficiency are critical. The unique design of our planetary gearboxes ensures smooth operation, reduced noise levels and optimal energy efficiency, making them ideal for demanding environments.

As planetary gearbox experts, we stand out for our deep expertise in the field and our commitment to innovation. Our products are designed to meet the diverse needs of our customers, providing customizable solutions to optimize performance and reliability. We are known for our excellent after-sales support, providing comprehensive technical assistance and timely service to ensure that every customer’s needs are met. Our company is constantly innovating and exploring new possibilities, pushing the boundaries of transmission technology and providing cutting-edge solutions that meet the ever-changing needs of the global market. Our reputation as a trusted partner in the production and sale of planetary gearboxes is a testament to our dedication to quality and customer satisfaction.

What are Planetary Gearboxes?

Planetary gearboxes are a type of gear system widely used in mechanical transmissions, known for their compact design and high torque capabilities. This gearbox consists of three main components: the sun gear, the planet gears, and the ring gear. The sun gear is at the center and drives the system, while the planet gears revolve around the sun gear and mesh with the outer ring gear. The planet gears are mounted on a carrier that rotates as the system operates. This unique configuration allows for even load distribution, resulting in improved efficiency and durability.

The main advantages of planetary gearboxes are their high torque density and compact size. Due to the multiple planet gears sharing the load, these gearboxes are able to handle high torque and heavy-duty applications without compromising on space. They also offer excellent energy efficiency, reduced noise levels, and high reliability.

How does a Planetary Gear box Work?

A Planetary gear box also referred to as an epicyclic or epicyclic gear box is among the most fascinating kinds of gear boxes that are available in motion control. They are commonly utilized in automobiles as a crucial component of automated transmissions.

Planetary Gear boxes are a form of gear box that has both output and input share the same center of rotation. It means that the central point of an input gear is rotated around the central point of the output gear, and the shafts for output and input are aligned.

what are planetary gearboxes used for?

Planetary gears are typically employed when weight and space are a concern, but the need for a substantial amount of torque and speed reduction are required. This is applicable to many industries, such as construction equipment and tractors, in which a lot of torque is required in order to power the wheels.

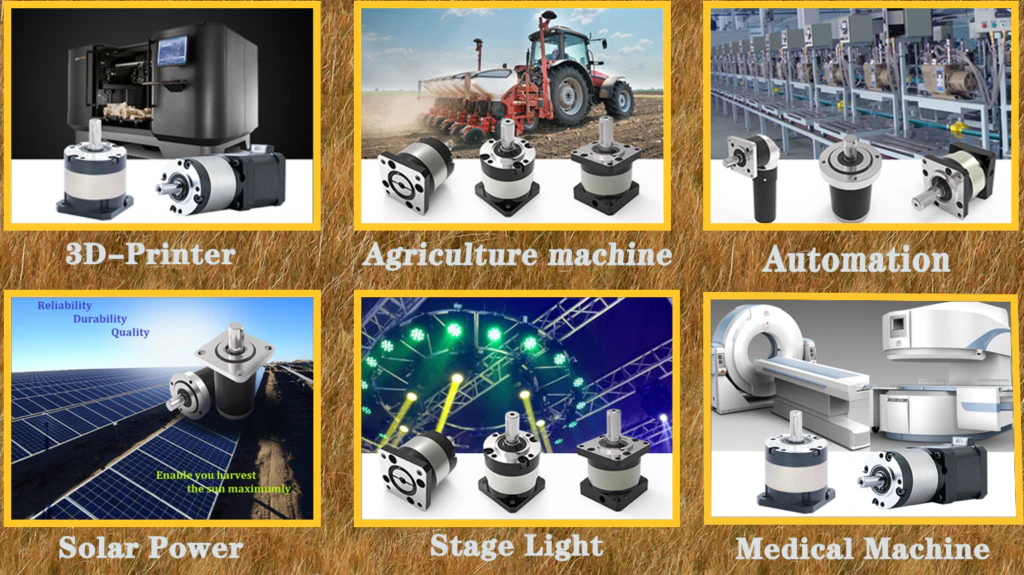

Planetary Gearboxes Application Industries

-

Automotive Industry

Planetary gearboxes are commonly used in automobile transmissions for smooth shifting and efficient power transfer. They also find application in electric vehicle drivetrains, automatic transmission systems, and steering systems. -

Industrial Machinery

In industrial settings, planetary gearboxes are used in conveyor systems, cranes, presses, milling machines, and robotic arms. Their ability to handle heavy loads while maintaining compactness makes them ideal for automation and material handling. -

Renewable Energy

Wind turbines rely on planetary gearboxes for converting mechanical energy from the blades into usable electrical power. Their high torque and reliability make them well-suited for this energy sector, especially in wind turbine drivetrains. -

Aerospace and Defense

Planetary gearboxes are used in aircraft systems, including flight controls, actuators, and landing gear systems. Their durability and precision are essential for high-performance aerospace applications. They also find use in military vehicles and robotic systems. -

Mining and Construction

In mining equipment, planetary gearboxes are used in excavators, drilling rigs, crushers, and haul trucks, where high torque and reliability are critical for heavy-duty operations. -

Robotics

Planetary gearboxes are integral to robotic actuators and servo motors. They provide precise control over motion and are often used in industrial robots, medical robots, and service robots. -

Agriculture

Tractors, harvesters, and other agricultural machinery often use planetary gearboxes for their ability to handle heavy-duty applications in farming environments, ensuring efficient power transmission and durability. -

Marine and Offshore

Planetary gearboxes are used in marine propulsion systems, winches, and offshore drilling rigs for their ability to provide reliable and efficient performance in harsh conditions. -

Packaging and Food Processing

Planetary gearboxes are found in packaging machines, conveyor belts, and food processing equipment where compact, high-torque solutions are necessary to maintain efficiency and speed. -

Electric Power Generation

In power plants, hydraulic power units, and electric generators, planetary gearboxes are used to convert rotational motion and provide high efficiency and torque for generating electricity.

Comparison of Planetary Gearboxes to other types of gearboxes such as helical or bevel gearboxes

| Feature | Planetary Gearboxes | Helical Gearboxes | Bevel Gearboxes |

|---|---|---|---|

| Design | Multiple planet gears around a central sun gear, with a ring gear on the outside. | Gears with teeth cut at an angle to the axis of rotation, typically parallel shafts. | Gears with conical teeth that mesh at an angle, usually used for perpendicular shafts. |

| Torque Handling | High torque density due to multiple load-sharing planet gears. | Moderate torque capacity, generally less than planetary gearboxes. | Moderate to high torque capacity, depending on design. |

| Size and Weight | Compact, high torque output for its size. Ideal for space-constrained applications. | Larger size for equivalent torque output. Typically less compact. | Larger than planetary gearboxes for the same torque, especially when high angles are used. |

| Efficiency | High efficiency due to load sharing across multiple gears. Typically 95% or higher. | Moderate efficiency, typically 85%–90% due to sliding friction between teeth. | Moderate efficiency, with some losses due to the angle of engagement. |

| Backlash | Low backlash, especially in high-quality planetary gearboxes with precision components. | Low to moderate backlash, depending on precision. | Generally higher backlash compared to planetary and helical gearboxes. |

| Noise and Vibration | Low noise and vibration due to even load distribution. | Low noise but can have more vibration at higher loads. | Higher noise and vibration, especially when high torque is involved. |

| Load Distribution | Excellent load distribution across multiple gears, increasing durability. | Load is concentrated on a single pair of teeth, which can reduce lifespan under heavy loads. | Load distribution is concentrated on fewer teeth, leading to higher wear and potential failure under heavy load. |

| Gear Ratios | Offers a wide range of gear ratios with minimal space. Can be designed for both high reduction and high-speed applications. | Offers wide gear ratios, but typically requires multiple stages for high reductions. | Limited to moderate gear ratios, often used for specific angle-related needs (e.g., 90 degrees). |

| Maintenance | Requires minimal maintenance, long-lasting due to efficient load distribution. | Requires more maintenance due to higher friction and wear over time. | Higher maintenance due to bevel teeth wear and the potential for backlash. |

| Applications | Used in high-torque, space-constrained applications such as robotics, automotive, wind turbines, and conveyors. | Common in industrial machinery, automotive transmissions, and linear actuators. | Used in applications where shafts need to be at right angles, such as automotive differential drives, machine tools, and bevel gear drives. |

| Cost | Typically higher due to the complex design and manufacturing process. | More affordable for standard applications with moderate torque requirements. | Generally more expensive than helical gearboxes, especially for high-quality bevel gears. |

| Strength and Durability | High strength and durability under heavy loads due to the distribution of torque. | Strong under moderate loads but can wear quicker under heavy or shock loads. | Strong, but durability is limited compared to planetary gearboxes, especially under shock loads. |

| Design Complexity | More complex due to the number of gears and the need for precise engineering. | Simpler design compared to planetary gearboxes. | Complex, especially when high precision is required for bevel angles. |

| Application Flexibility | Highly flexible, with the ability to design for specific torque and speed requirements. | Suitable for most general applications, but less flexible than planetary gearboxes for specific needs. | Primarily used for specific applications where angle conversion is required. |

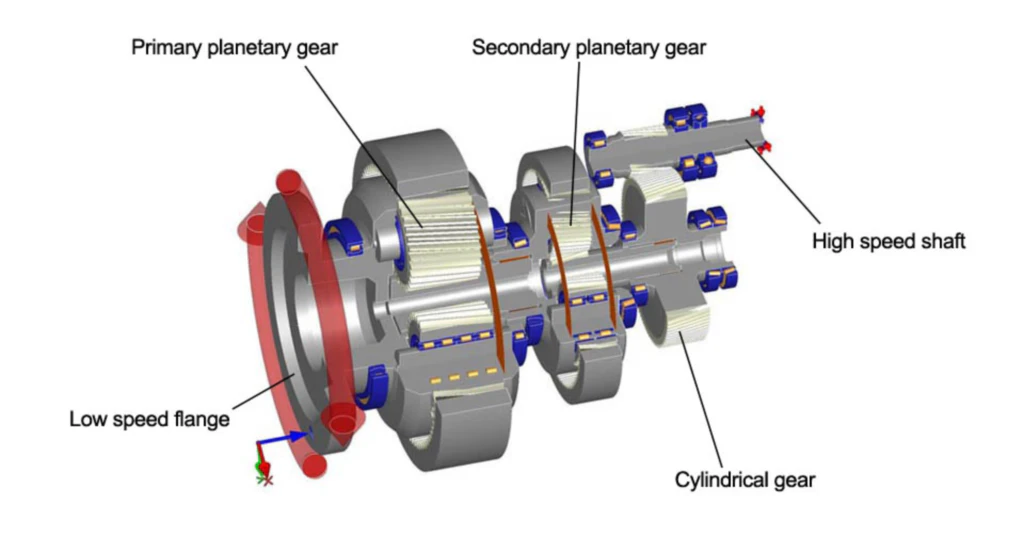

The main components of Planetary Gearboxes

Sun Gear

The sun gear is the central gear in a planetary gearbox. It is the input gear that is powered by the driving motor or other power source. The sun gear drives the planet gears, making it the primary source of motion in the system.

Planet Gears

The planet gears are the gears that orbit around the sun gear. They are typically mounted on a rotating carrier and mesh with both the sun gear and the ring gear. Planet gears distribute the load across multiple gears, which improves torque handling and reduces wear. They are the core of the planetary system, as they transmit motion and torque between the sun gear and ring gear.

Planet Carrier

The planet carrier holds the planet gears in place and allows them to rotate around the sun gear. The carrier also transmits the torque from the planet gears to the output shaft. The carrier rotates in sync with the planet gears, ensuring smooth operation and even distribution of load.

Ring Gear

The ring gear is the outer gear that meshes with the planet gears. It encircles the planet gears and works with the sun gear to transmit power. The ring gear can be used as the output gear, or it may remain stationary, depending on the specific design of the gearbox. It plays a crucial role in determining the gear ratio in a planetary system.

Output Shaft

The output shaft transmits the rotational motion from the planetary gearbox to the rest of the mechanical system. It is typically connected to the planet carrier or the ring gear, depending on the specific arrangement and gear ratio. In some cases, the output shaft may be driven directly by the sun gear.

Bearing

Bearings support the rotating components of the gearbox, reducing friction and wear while ensuring smooth operation. Bearings are typically used to support the planet carrier and planet gears.

Housing

The housing is the outer casing that holds all of the components of the planetary gearbox together. It protects the internal gears from debris, contaminants, and external damage, while also providing structural support for the other parts.

Why Planetary Gearboxes are more efficient than other types of gearboxes

1. Load Distribution Across Multiple Gears

In a planetary gearbox, the load is distributed across multiple planet gears, unlike in helical or spur gearboxes, where the load is carried by only one or two gears at a time. This even distribution of load reduces the risk of wear and tear on individual gears and minimizes energy loss, resulting in higher efficiency.

2. Compact Design

Planetary gearboxes are designed with a compact, concentric structure, meaning that the input and output shafts are aligned along the same axis. This compactness allows for high torque output without taking up a lot of space, making them more efficient in applications where space is limited.

3. Minimal Gear Slippage

Due to the way the planet gears mesh with the sun and ring gears, there is less chance of gear slippage or misalignment, which often leads to energy losses in traditional gear systems. The planet gears are always in contact with both the sun and ring gears, ensuring consistent and stable torque transmission.

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Maintaining Planetary Gearboxes

1. Regular Lubrication

Importance: Proper lubrication is crucial for reducing friction and wear between the gears. The gears in a planetary gearbox operate under high stress, and without sufficient lubrication, components may wear prematurely, resulting in reduced efficiency and eventual failure.

Maintenance Tip: Check the lubricant levels regularly and replace the lubricant according to the manufacturer’s recommendations. Use the correct type and viscosity of oil or grease, as specified for the gearbox’s operating conditions. Over-lubrication can cause overheating, while under-lubrication leads to excessive wear.

2. Monitoring Operating Temperature

Importance: Planetary gearboxes can generate significant heat, especially when under heavy load. Overheating can lead to increased wear, oil degradation, and eventual failure of the gearbox components.

Maintenance Tip: Ensure the gearbox operates within the recommended temperature range. Use temperature sensors or monitoring systems to keep track of operating temperatures. If the temperature exceeds the safe limits, check for lubrication issues or excessive load, and ensure proper cooling is in place.

3. Inspecting for Vibration and Noise

Importance: Excessive vibration or unusual noise can indicate a problem with the planetary gears, such as wear, misalignment, or imbalance. These issues can lead to more serious mechanical failures if not addressed promptly.

Maintenance Tip: Perform regular checks for unusual vibrations or noises. If any irregularities are detected, inspect the gears, bearings, and shafts for wear, and perform necessary repairs or replacements. Regular vibration monitoring can also help detect developing issues before they become major problems.

4. Checking for Backlash

Importance: Backlash refers to the slight movement between gears when the direction of motion is changed. Too much backlash can indicate wear in the gear teeth, which can reduce the gearbox’s performance and accuracy.

Maintenance Tip: Measure backlash periodically, especially in applications requiring precision. If backlash exceeds the allowable limits, inspect the planet gears, sun gear, and ring gear for wear, and replace components as necessary.

5. Regular Inspection of Bearings

Importance: Bearings in planetary gearboxes support the rotating components (such as the planet gears and planet carrier). Over time, bearings can wear out due to constant friction, leading to increased vibration, noise, and potential failure.

Maintenance Tip: Inspect the bearings regularly for signs of wear, rust, or contamination. If bearings are damaged or show excessive wear, replace them promptly to avoid further damage to the gearbox.

6. Ensuring Proper Alignment

Importance: Misalignment of the input and output shafts can lead to uneven load distribution, which puts excessive stress on the planetary gears and bearings. This can cause accelerated wear and potential failure.

Maintenance Tip: Regularly check the alignment of the shafts and ensure they are properly mounted and positioned. Misalignment can often be corrected with adjustment, but in some cases, it may require a redesign or repair of mounting brackets or other components.

7. Sealing and Contamination Control

Importance: Seals prevent contaminants such as dirt, dust, and moisture from entering the gearbox and interfering with the gears and lubrication. Contaminants can cause accelerated wear, corrosion, and mechanical failure.

Maintenance Tip: Regularly inspect seals for any signs of damage, cracks, or leaks. Replace seals as needed and ensure that the gearbox is not exposed to excessive dust, dirt, or moisture. Consider using filtration systems or breathers to reduce contamination.

8. Load Monitoring and Management

Importance: Overloading a planetary gearbox can cause it to operate beyond its design limits, leading to overheating, excessive wear, and potential failure. It’s essential to keep the load within the specified range for optimal performance.

Maintenance Tip: Regularly monitor the load conditions during operation. Ensure that the gearbox is not subjected to sudden shocks, high-impact loads, or overloading. In some cases, installing load sensors can help keep track of operating conditions.

9. Cleaning and Debris Removal

Importance: Dust, dirt, and debris can cause friction and wear between gears, bearings, and seals. Over time, these contaminants can degrade performance and efficiency.

Maintenance Tip: Keep the exterior of the planetary gearbox clean. Remove any dirt or debris around the gearbox, especially around the vents and cooling systems. Ensure that air filters or other protective measures are in place to reduce contamination.

10. Periodic Gear Inspections

Importance: Gears can experience wear due to repeated contact and load. Regular inspections can identify early signs of gear wear, tooth damage, or pitting that could lead to failure.

Maintenance Tip: Disassemble the gearbox periodically (depending on the operating hours and conditions) to inspect the gear teeth for any signs of damage. Check for pitting, scoring, or cracks. Replace worn gears as necessary to prevent further damage.

11. Oil Filter Replacement

Importance: Oil filters help to remove contaminants from the lubricating oil, ensuring that the gearbox components are well-lubricated and protected from wear.

Maintenance Tip: Replace oil filters as per the manufacturer’s recommendations. A clogged or dirty oil filter can cause poor lubrication, resulting in overheating and wear.

Why choose our company?

1. High-quality products: Our company is committed to providing the highest-quality Planetary Gearboxes. Our products are precision-engineered and manufactured using advanced materials to ensure durability, reliability, and consistent performance.

2. Comprehensive Service: We pride ourselves on providing excellent customer service. Our professional team is ready to answer your questions, provide technical support, and provide solutions tailored to your needs.

3. Competitive Prices: Our company offers competitive prices without compromising quality. We believe in creating value for our customers and work hard to ensure our products fit every budget.

4. Excellent after-sales support: We know a product is only as good as the support you receive after purchasing it. Our company provides comprehensive after-sales services, including timely repair, replacement, and maintenance, ensuring that your Planetary Gearboxes is in optimal condition for a more extended period.

5. Rich product range: Our company provides a variety of Planetary Gearboxes shafts to meet different applications and requirements. We can provide you with the right product.